The Magnetic Phenomenon in Stainless Steel Screws – A Metallurgical Insight

- Posted by: Admin

- 2025-05-19

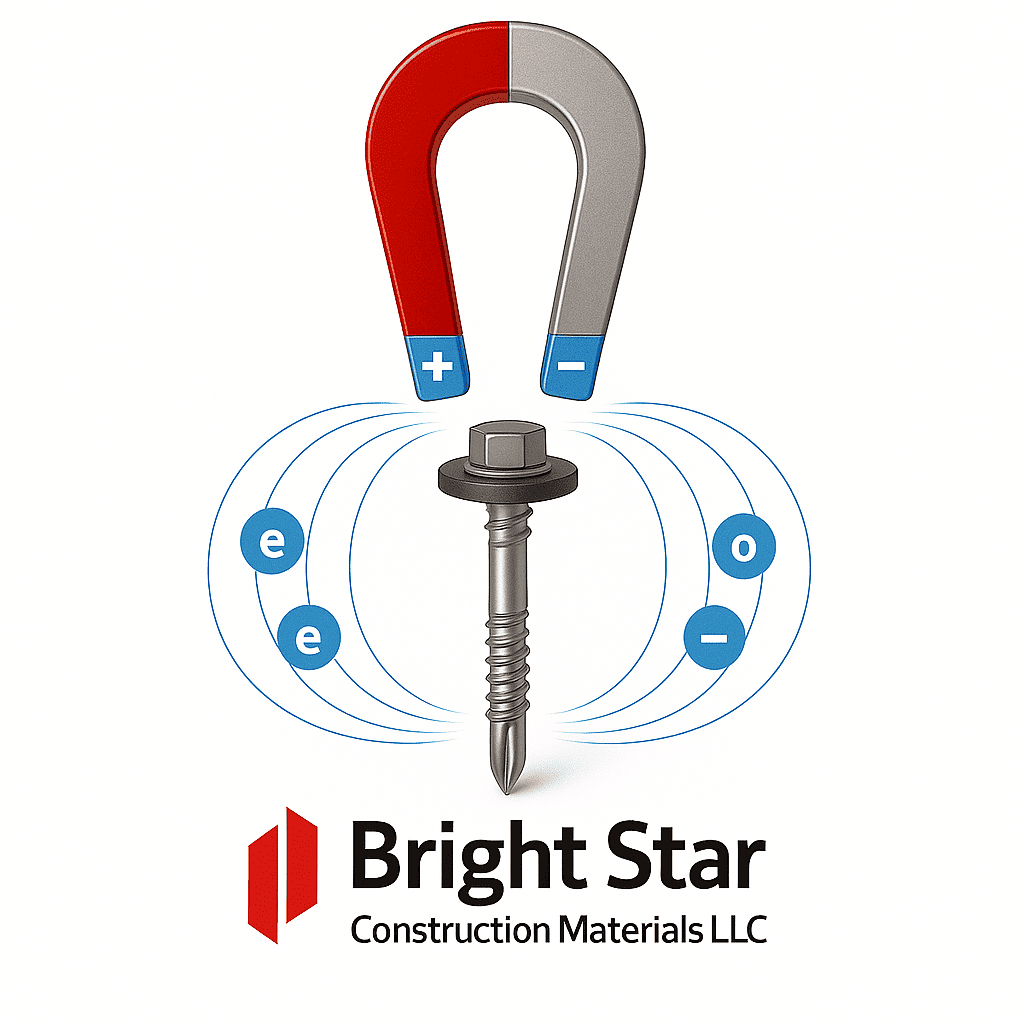

Stainless steel screws, commonly expected to be non-magnetic, often exhibit magnetic properties—particularly around the head. This phenomenon has led to inquiries from both technical and non-technical users. Through this case study, we explore the underlying metallurgical and manufacturing causes, focusing on alloy composition and cold forming processes.

Material Background

Most stainless steel screws are manufactured from austenitic stainless steel, renowned for its excellent corrosion resistance and non-magnetic behaviour in the annealed state. This family of stainless steels contains iron (Fe), chromium (Cr), and nickel (Ni), with occasional additions of manganese (Mn) and molybdenum (Mo) to enhance performance. Austenitic stainless steel typically features a face-centred cubic (FCC) crystal structure, which is stable and non-magnetic under normal conditions.

The Cold Forming Effect

Cold forming processes—such as cold heading and cold forging—are widely used to shape screws efficiently without heating. However, these processes introduce significant plastic deformation. Under intense mechanical stress, portions of the austenitic structure can transform into martensitic stainless steel, which has a body-centred tetragonal (BCT) structure and is inherently magnetic. Because of this slight magnetic effect and change in microstructure, the corrosion resistance properties of austenitic stainless steels remain unchanged. This transformation is localized to areas experiencing the highest deformation—most notably, the screw head. The newly formed martensitic regions contain magnetic domains that respond to external magnetic fields, causing the screw to exhibit partial magnetism.

Conclusion

The magnetic response in stainless steel screws is not a material defect, but a scientifically explainable outcome of alloy behaviour and mechanical processing. Understanding this transformation is crucial for engineers and end-users when selecting fasteners for sensitive applications where magnetism may be a concern.